Transport Conveyor

The transport conveyor is designed to transport baggage throughout the terminal smoothly and efficiently. It is designed to handle product horizontally and at any degree of incline / decline up to a maximum 18° angle where elevation changes are required.

General transport conveyor is made up of several different modules bolted together to form a single conveyor.

Whilst the design of the conveyor modules has been standardised, it allows for many different configurations of length, top of belt height and incline / decline angle.

Low side panel height sections are also available to suit loading and unloading conveyor as well as collector conveyor configuration.

General Dimensions

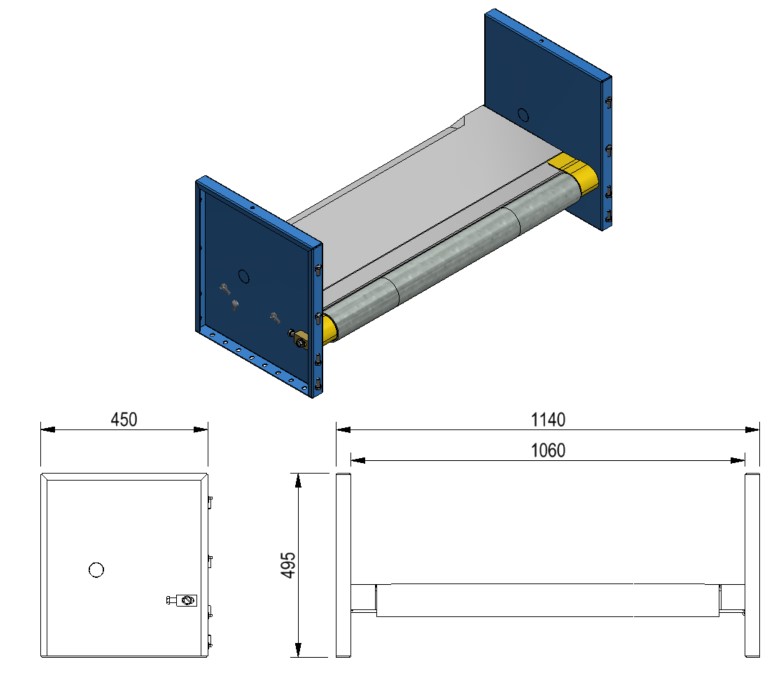

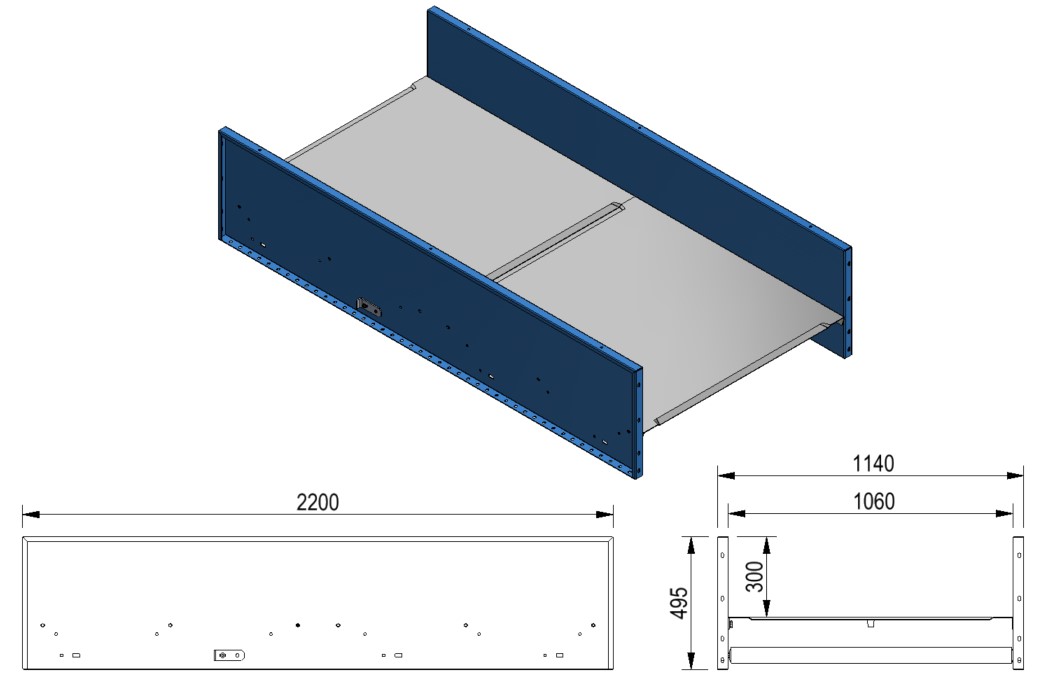

Intermediate Module

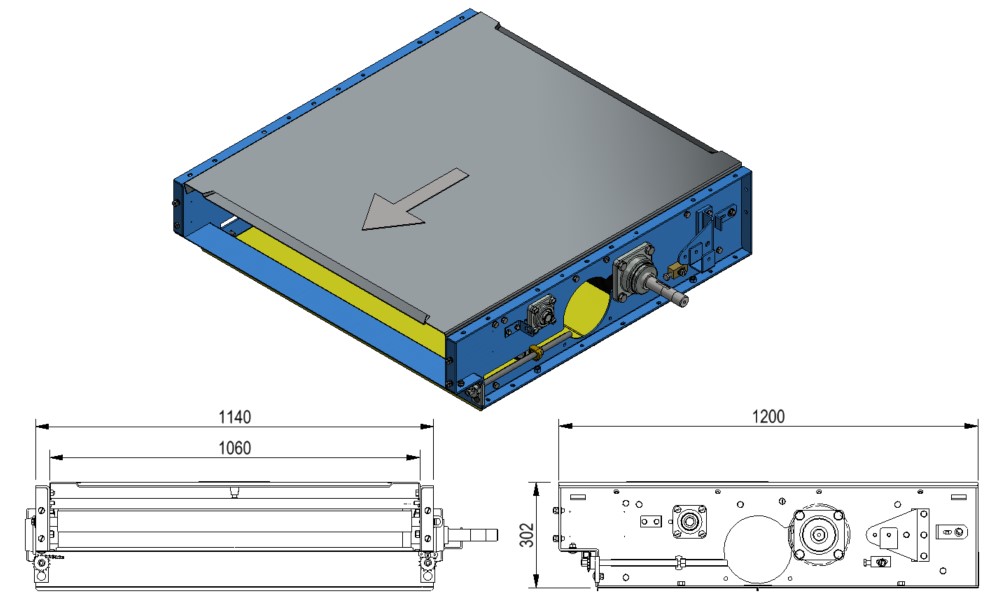

Drive Unit Module

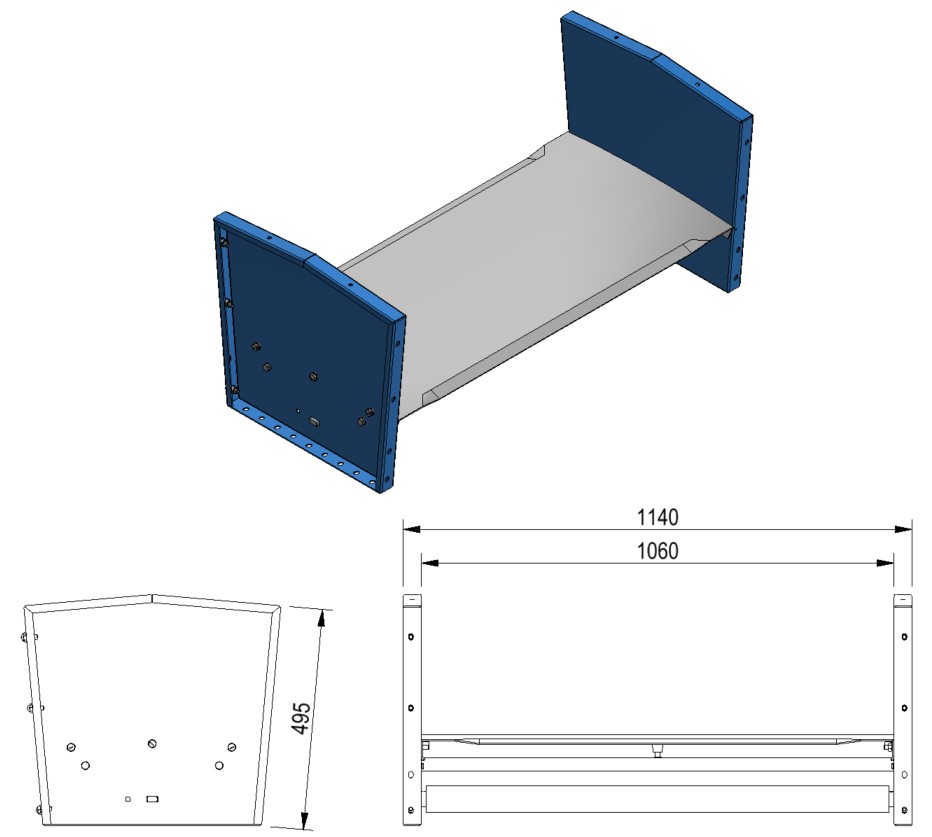

Breakover Module (10° shown)

Drive Unit Module

Key Features

- End rollers with profiled finger guards to eliminate trap points for personnel and product.

- Internal bearings are fitted to head, tail and take-up rollers for ease of maintenance and quick changeover.

- Final drive between the gearbox and drive pulley is via a direct shaft mounted gearmotor.

- Cut outs are provided in the conveyor frame to allow for rollers to be removed from the side.

- Screw type belt take-up design to allow adjustment from one side.

- Can be floor mounted to as low as 300 mm top of belt.

Parts of Transport Conveyors

- Head / Tail Module: Is used at both ends of the conveyor and houses the end rollers.

- Drive Unit: Accommodates the motor gearbox and provides the drive and take-up of the conveyor belt.

- Intermediate Section: Standard sections are 2200 mm and 1100 mm long however, special length sections are made to suit the required conveyor length.

- Breakover or Decline: Used when a change to an incline is required and provides a smooth transition due to the large 3000 m radius.

Technical Specifications

- Intermediate Side Frames: The conveyor frame is typically 495 mm H x 40 mm W channel construction formed from 3 mm thick powder coated mild steel.

- Slider Beds: The slider bed is constructed from 3 mm galvabond mild steel set between the channel frames and rigidly braced with galvabond mild steel cross braces.

- Drive Frame: 5 mm thick mild steel formed channel 290 mm deep with 40 mm flanges.

- Breakover: A heavy duty return roller is used at the change of belt direction that is 60 mm in diameter with 5 mm nominal wall thickness mild steel tubing.

- Belting: To suit individual projects. Typically smooth top belting is used on collector conveyors.