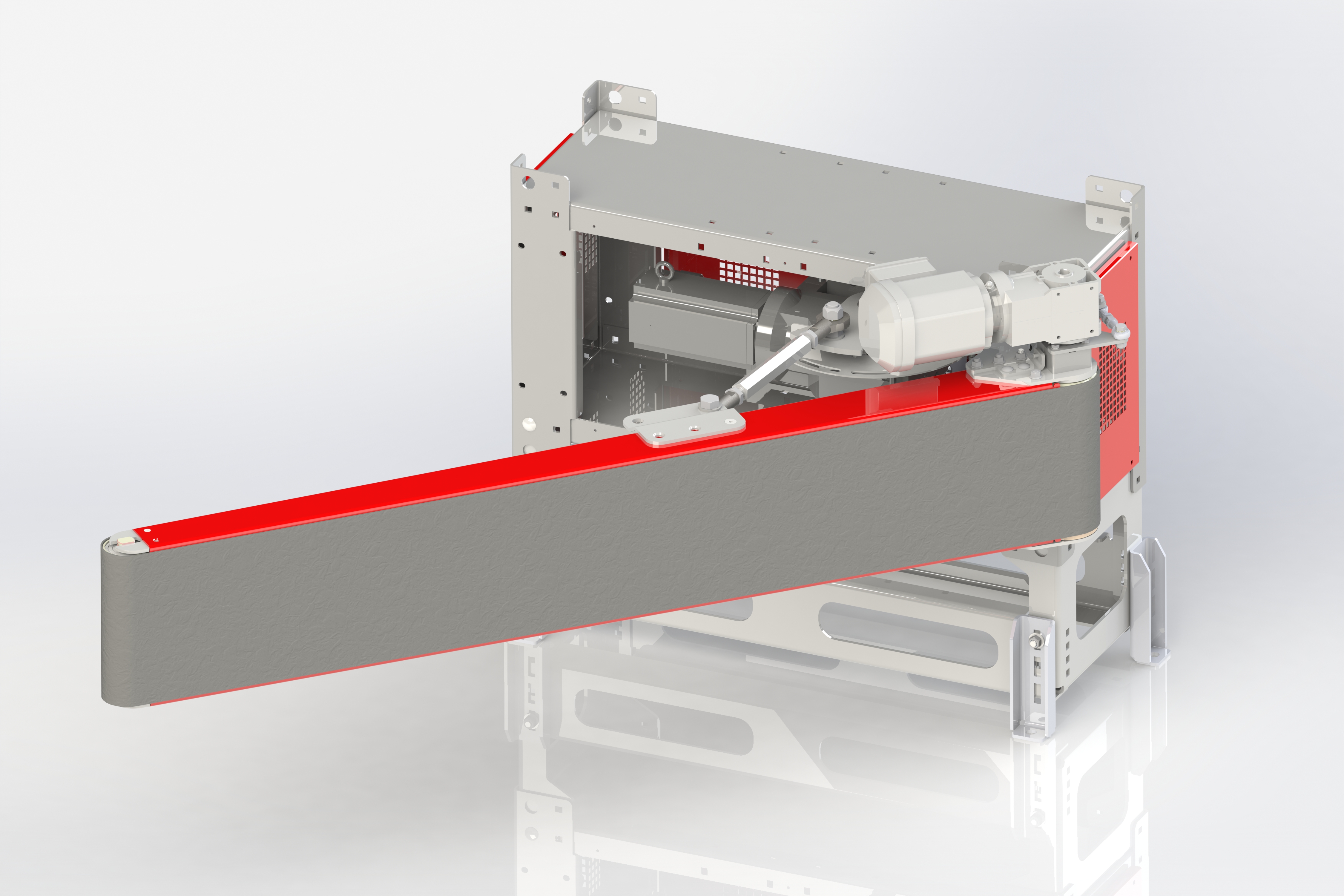

Plough Divert

The Fast Acting Belt Plough has been designed to handle and sort a wide range of products, with minimum impact to the bag during the plough divert operation.

The unit has been design to be used in conjunction with the Ansir range of Transport and Queue conveyors and is of modular design enabling the unit to be supplied to suit the customer's specific needs.

Fast Acting Belt Ploughs perform:

- Line splitting of flow from one line into two.

- Separation of single bags from a continuous stream of baggage.

- As an inline sortation system.

General Dimensions

Fast Acting Plough

Key Features

- Single horizontally mounted plough arm

- Separate drive for divert mechanism and plugh arm.

- Robust welded frame construction.

- Drive and end pulleys are fitted with grease packed precision bearings.

- 360° Motor rotation for one cycle which prevents plough arm over-run

Technical Specifications

- Frame: Welded channel frame construction. The arm of the plough is of steel box section with a slider bed surface over which the plough belt runs. The diverter belt runs between vertically oriented drive and end pulleys. Belt tensioning is achieved by adjusting the end pulley.

- Plough Belt Drive: V-belt to absorb shock loading.

- Pulleys: The drive and end pulleys are fitted with precision bearings. The drive pulley is mounted on an extended drive shaft, which is driven by a geared motor.

- Drive Shaft / Divert Mechanism: A machined drive flange is fixed to the output shaft of the gearbox which in turn is connected through a link bar mechanism to the main pivoting shaft of the plough arm.

- Divert Mechanism - Motor Gearbox: A shaft mounted motor gearbox connects directly to the conveyor drive roller shaft. The transmission equipment is adequately sized for the load, speed, temperature and operating conditions specified. The drive flange completes 360° rotation of travel for one full plough cycle which prevents over-run.

- Sensors: A shaft mounted motor gearbox connects directly to the conveyor drive roller shaft. The transmission equipment is adequately sized for the load, speed, temperature and operating conditions specified. The drive flange completes 360° rotation of travel for one full plough cycle which prevents over-run.