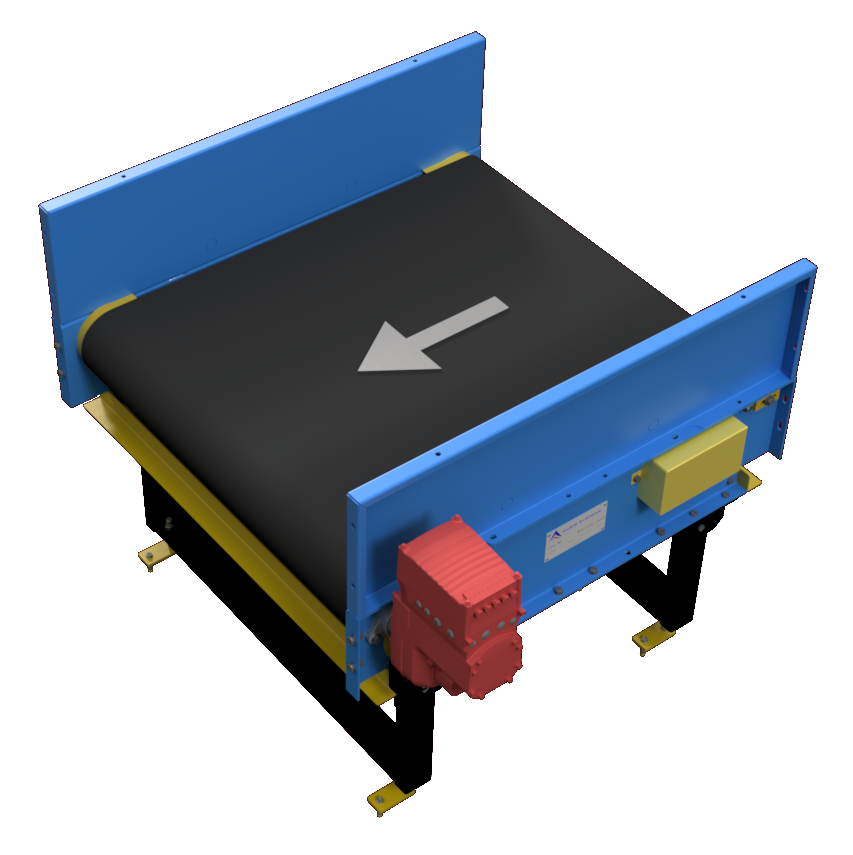

Metering Conveyor

The metering conveyor is generally used as a queuing conveyor prior to conveyor junctions, merges or places where accumulation or separation is required.

The conveyor is designed to cope with frequent stop /starts.

Whilst the basic design of the conveyor is standard, it is sufficiently flexible to accommodate variations in belt type, sidewall height, overall length and conveying speed.

General Dimensions

Metering Conveyor

Key Features

- End rollers with profiled finger guards to eliminate trap points for personnel and product.

- Internal bearings are fitted to head, tail and take-up rollers for ease of maintenance and quick changeover.

- Final drive between the gearbox and drive pulley is via a direct shaft mounted gearmotor.

- Cut outs are provided in the conveyor frame to allow for rollers to be removed from the side.

- Screw type belt take-up design to allow adjustment from one side.

- Flexible design that allows for variations in length up to 2500mm. The standard metering conveyor is typically 1200 mm in length.

Technical Specifications

- Frame: 5 mm thick mild steel formed channel 290 mm deep with 40 mm flanges.

- End Roller: Machined crowned 90 mm diameter 6 mm nominal wall thickness mild steel tubing with UCS208 press fit, internally mounted, grease packed, sealed for life, precision bearings that mount to a non rotating 40 mm bright steel shaft.

- Motor / Gearbox: A shaft mounted motor gearbox connects directly to the conveyor drive roller shaft. The transmission equipment is adequately sized for the load, speed, temperature and operating conditions specified.

- Side Guides: 3.0 mm mild steel formed to a height of 300 mm above the conveyor bed and rigidly fastened to the conveyor. Guides are installed to eliminate any interference with baggage flow and to prevent damage.

- Belting: 2505 x 1000 mm LG endless PVC fire rated belt (typical for 1200 mm long conveyor).