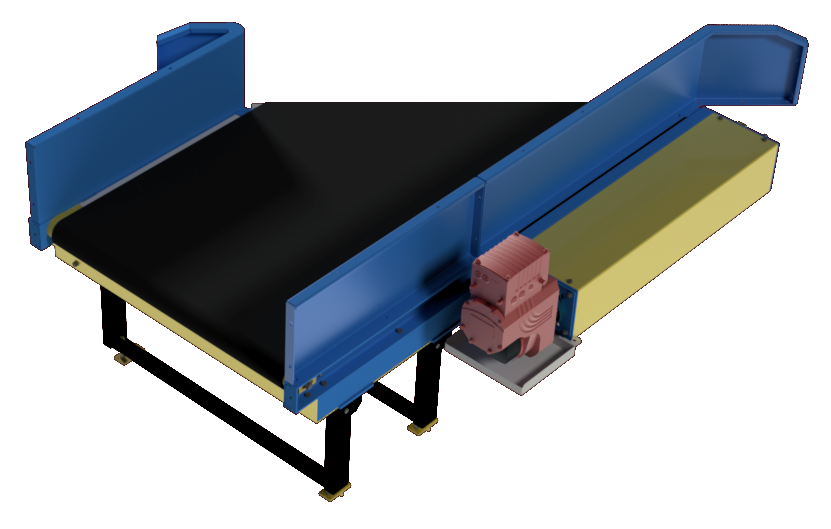

Merge Conveyor

A merge is a belt conveyor with a 45° angled connection edge that enables the merging of two conveyor lines. Typically used with additional sorting conveyors they provide for a smooth flow of baggage from one line to another.

45° merge conveyors are manufactured in 2 lengths measured along the centreline of the conveyor from the tail end to the discharge / head end. They can be provided at either 1500 mm or 1775 mm centre length.

General Dimensions

Merge Conveyor

Key Features

- Tail end roller with profiled finger guards to eliminate trap points for personnel and product.

- Internal bearings are fitted to tail and take-up rollers for ease of maintenance and quick changeover..

- Final drive between the gearbox and drive pulley is via a direct shaft mounted gearmotor.

- Hinged front section that allows the use of an endless belt.

- 30mm dia nose bar reduces transitional gap between merge and receiving conveyor. Machined flat on face reduces contact patch between the belt and nose bar.

Technical Specifications

- Frame: Two separate frames are constructed with the front 45° frame section hinge mounted to allow for an endless belt to be fitted. The frame is powder coated finish.

- Head Nose Bar: The front non-rotating nose bars are made from 32 mm diameter bright steel bar with a machined flat that provides an airgap between the belt for reduced friction and cooling. The nose bars are fastened to the frame with a series of counter bored 5 mm cap screws. grease-packed sealed bearings.

- Motor / Gearbox: A shaft mounted motor gearbox connects directly to the conveyor drive roller shaft. The transmission equipment is adequately sized for the load, speed, temperature and operating conditions specified.

- Side Guides: 3 mm mild steel formed to a height of 300 mm above the conveyor bed and rigidly fastened to the conveyor. Guides are installed to eliminate any interference with baggage flow and to prevent damage.

- Belting: 4920 x 1000 mm LG endless PVC fire rated belt