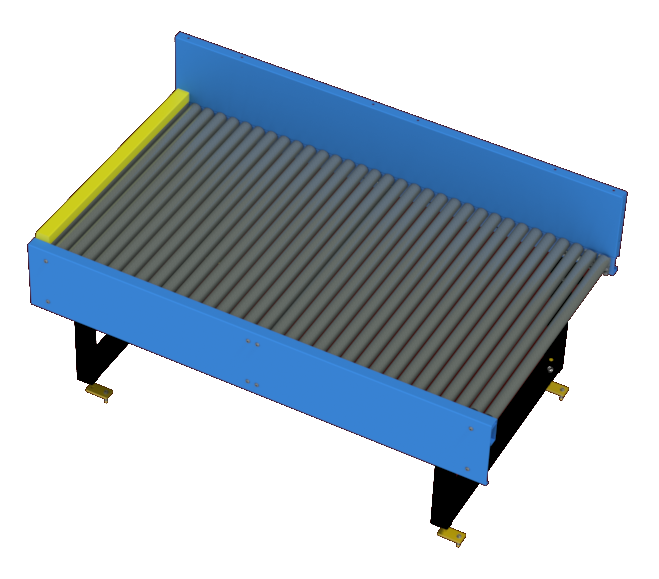

Gravity Roller Conveyor

Non powered accumulation of baggage / product. The conveyor can be placed flat for manual movement of the bag along its length or slightly declined to let gravity slowly transit the bag.

Typical applications are:

- At the end of a make up lateral for accumulation.

- Manual processing areas to allow for the easy movement of baggage / product by the operator.

General Dimensions

Between Frame Rails (BFR)

Key Features

- Light weight and rigid conveyor frame. With safety edge fold. Cross bracing at approx. 900mm centers.

- Pop out rollers provided when butting up to a powered conveyor for safety.

- End stops provided as required to prevent baggage / product from falling off the conveyor.

- Powder coated conveyor frame and leg supports as standard (other finishes available on request).

- Individual sections up to 3000mm in length.

- Waterfall effect to assist baggage transfer between conveyors.

Types of Gravity Roller Conveyors

- Between Frame Rails (BFR): Typically 1060mm to match standard powered conveyor widths. (1450 BFR with split rollers can be provided for oversize product).

Technical Specifications

- Rollers: 50mm dia galvabond finish with semi precision bearings. Spring loaded hex shaft for ease of installation and remova

- Frame: 2.5mm mild steel, formed C-shaped channel 40mm x 90mmx 40mm.

- Supports: Folded mild steel construction with adjustable threaded rod feed for easy levelling and adjustment.

- Finish: Powder coated frame and supports.