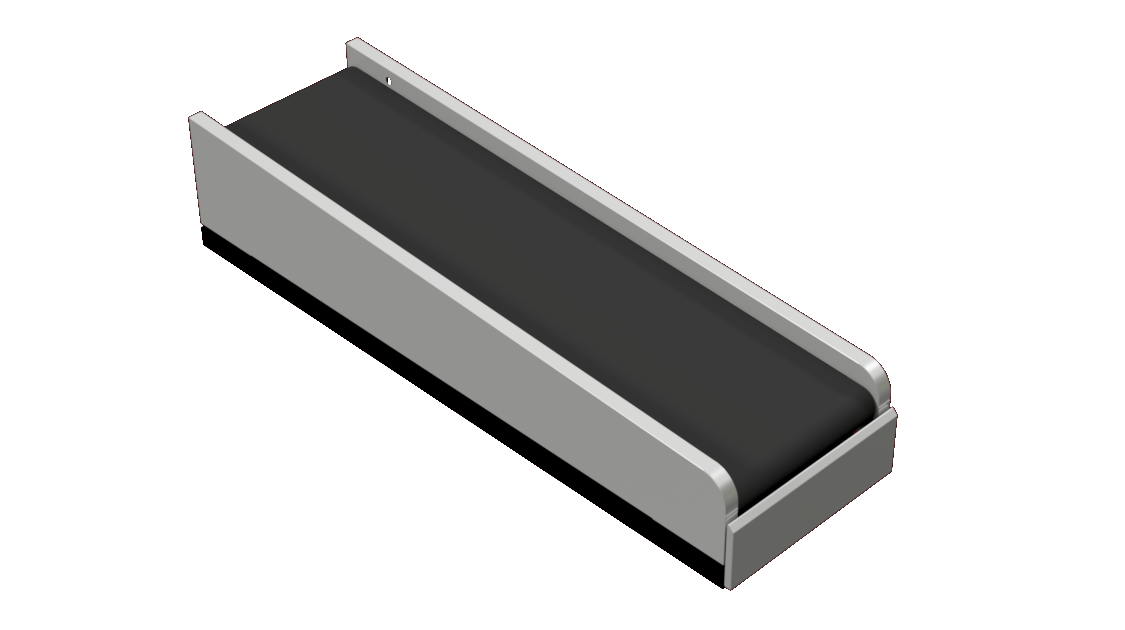

Check-In Conveyor

As the first point of interface between passenger and baggage handling system, the check-in conveyor must be safe, reliable and functional.

The check-in conveyor is designed to weigh, label and dispatch baggage onto the collector / take-away conveyor without the need of manual lifting by the check-in operator.

Ansir check-in conveyors are designed with ergonomics and safety in mind. The tub load feature (available in the two and three stage design) has proven to reduce the amount of lifting the check-in agent has to perform and makes for simpler system operation.

Whilst the basic design of the conveyor has been standardised, it is sufficiently flexible to accommodate variations in height and configuration.

General Dimensions

One Stage Check-In

Two Stage Check-In

Key Features

- High-quality stainless steel finish.

- Roll-in/roll-out for ease of maintenance and cleaning.

- Fitted with quick-disconnect plugs.

- Easy removal of side panels with no tools required.

- Passenger tamper-proof weigh scale.

- Waterfall effect to assist baggage transfer between conveyors.

Types of Check-in Conveyors

- Single Stage: Used to weigh, label, and dispatch the bag onto the collector/takeaway conveyor.

- Two Stage: Baggage weighing and labeling operations are carried out on the scale conveyor, then transferred to the induct conveyor for accumulation/queuing before induction onto the collector/takeaway conveyor.

- Three Stage: Separate conveyors are used for weighing, labelling and dispatch of the bags for maximum flexibility. Baggage weighing operations are carried out on the scale conveyor and then transferred to the labelling conveyor for attaching of the bag tag. The bag is then transferred onto the induct conveyor for accumulation / queuing and controlled induction onto the collector / take-away conveyor.

Technical Specifications

- Drive Pulley: Crowned 113mm diameter with a 0.37kW internal motor providing a conveyor speed of 0.5m/sec.

- End Roller: Crowned 90mm diameter roller with precision ball bearings and grease-packed sealed bearings.

- Cladding: 2mm thick 304 grade stainless steel with a brushed finish.

- Side Panels: Folded construction with aesthetically pleasing radius front edges.

- Belt: Flame retardant two-ply PVC, offered with both vulcanized and mechanical lacing depending on customer preference.